The Problem With Wine Cooling Units

Today, the vast majority of wine connoisseurs control their wine cellar temperature using a compressor-powered cooling systems. The same technology is also used for small wine cellars and wine fridges. It relies on the compression of a gas to create cool. By compressing the gas, the wine cooling unit creates heat. This heat is then unloaded. The cooling system then proceeds to start the reverse process through a tiny hole. When the pressure of the gas collapse, the opposing reaction happens: cold air is created! Can we build a better wine cellar cooling units?

The first cooling systems, dated from the 1800s, were functioning by compressing air and sending it through a small orifice and ice was created. Today, instead of using air as a gas, Freon is utilized—a sophisticated gas that offers better results in terms of efficiency, temperature control and resistance to pressure. In time, compressor-based wine cooling systems emerged into the market using the same technology as refrigerator . They were and still are designed to deliver low temperature; much lower than the optimal temperature of 14 to 16 °C required to age wine perfectly. Compressors used in wine cellars are built to keep a temperature of 4–5 °C.

When using a compressor powered wine cooling units in your cellar you are asking the technology to deliver a much higher temperature than what it was originally built for. To make matters worse, the cooling loop that is designed to reach much colder temperatures condenses water to its contact (much like a bottle of water that comes out of the fridge in the summer) thus drying out the air of the wine cellar. This is why today we are observing cellars equipped with a wine compressor to cool the room and a humidifier to compensate for the drought generated by it. Note that both systems consume a lot of energy, which significantly increases the cost of maintaining a cellar over time. On the one hand, cellar cooling units remove all moisture from condensation and, on the other hand, the humidifier produces more and more water to maintain moisture levels at the desired levels for safe keeping the wine. In the end, the two systems fight each other literally.

The core problem with the technology used today originate from the lack of control we have on the temperature of the cooling fluid. Let say you want to maintain your cellar at a constant temperature of 14 °C. The system will chill the fluid to 4 or 5 ° C. and the temperature of the cellar will gradually drop from, let say 16 °C to 13 °C. At this point, the compressor will stop, and the temperature will start rising again. No matter how precise your system is, your cellar will always experience constant fluctuations of at least of 1 or 2 °C, sometimes much more. Those continued fluctuations are harmful to your wine and the incessant switch on and off of the compressor reduces its life span. This is why many wine lovers have to replace their cooling units after 5 or 6 years of usage. To be successful, a wine cooling units using a compressor would require a much larger surface to compensate for the temperature of the cooling fluid. However, no manufacturers to date have explored ways to improve and adapt their cooling systems to the cellars. Close to 100% of the compressors available on the market are engineered for refrigerators and are not fit to maintain a stable higher temperature.

The compressor wine cooling systems function intermittently, which affects the stability of the temperature in the wine cellar. To make things worst, every time heats enters the cellar because someone opens the door, the cycle is accentuated. The more traffic there is in your wine room, the worst it gets. This creates inevitable cycles of cooling, followed by gradual or rapid reheating which is far from optimal to keep wine for the long run. If you ever have visited a European wine cellar, you realized that the rooms are usually deep underground with walls of stones or clay. They provide constant temperature and humidity, no hourly fluctuation of 2 or 3 degrees. Yes, the temperature will change according to the season, but those changes happen gradually over a long period and are considered as positive to the evolution of the wine.

What Is the Solution?

Technically, the perfect wine cooling units would require a cooling liquid very close to the temperature at which the cellar needs to be maintained. As an example, if the required temperature is set at 15 °C and the cooling liquid is maintained at 14 °C, there would never be any condensation, which would remove the need to artificially add humidity to the room. A team of engineers from Montreal spend years analysing the problem and recently launched The Cube°, a new approach to temperature and humidity control for wine cellars.

From the start their ultimate goal was to maintain a constant temperature and humidity level within the wine room. To achieve this, they needed to develop a system where the cooling liquid temperature could be set at the level required by the consumer. Instead of having to deal with a constant 4–5 °C produced by the compressor, they created a system where it is the temperature of the cooling agent that can be set at the desired target. By doing so they eliminate the dry air problem in the wine cellar and all condensation. The key to their success was to discard the compressor from the equation…

The Cube°, Revolutionary Wine Cooling Units

The Cube° contains no compressor. In fact, it is using a semiconductor technology, inspired by the Peltier effect, an effect whereby heat is emitted or absorbed when an electric current passes across a junction between two materials. The e-cool technology found in The Cube° works by having one side of the source element creating cold, and the other side, heat.

Thermoelectric systems have existed for a long time, this precise technology has been unfortunately very inefficient, there units on the market on average present a low coefficient of performance of 20%. However, when done professionally with the e-cool technology (100% COP), thermoelectricity is the most environmentally friendly and economical way (apart from digging your own cellar …) to maintain a constant temperature in a piece. The Cube°, contrarily to traditional mechanical systems, has no moving parts which offers an immense improvement to the lasting capabilities over wine cooling units with compressors.

Its technology delivers a wine cooling systems which adapt the temperature of the cooling liquid constantly, therefore the system is never interrupted. The Cube° provides the stability of temperature and humidity necessary to age wine in the best of conditions at all time.

How The Cube° Wine Cooling Unit works

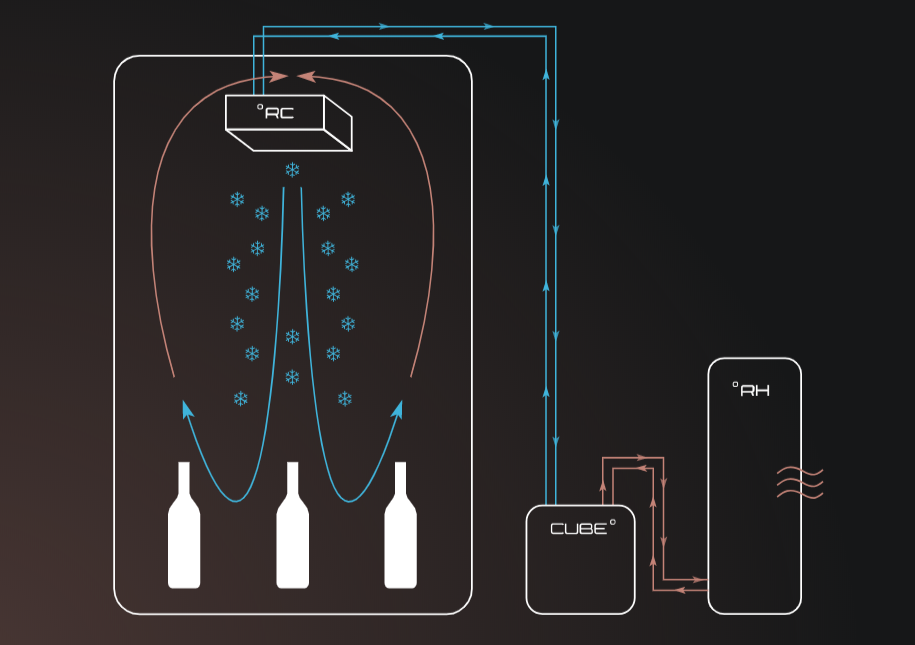

– Cube°: The brain of your wine cellar, the Cube° controls the wine cooling unit and ensures a constant temperature in your cellar with the circulation of cold and warm water loops.

– °RC: The cooling unit represents the heart of the wine cellar. Connected to The Cube°, the heat is captured to maintain ideal wine maturing conditions.

– °RH: The unit extracts heat from the cellar’s interior and pushes it into another room.

4-Steps Function to keep your wine cellar temperature stable

-

The °RC extracts the warm air from the cellar and routes it to The Cube°;

-

The heat then flows into two separate loops, each filled with pure distilled water;

-

The heat transfer occurs inside The Cube° thanks to its e-cool technology;

-

The °RH takes the heat and pushes it into another room.

In summary, the system brings forth these advantages:

- The humidity in the cellar is not fully removed by the cooling system;

- No need to drain the water created by condensation as this process simply never happens;

- The system uses very low levels of energy by never passing the famous 1000 calories per gram mark;

- Whisper-quiet, at only 23 dBA, The Cube° emits as little noise as an office computer;

- 20-year lifespan system;

- Delivers extremely stable temperatures with variations as small as 0:01 °C;

- Available for large room or small cellar for condos.

This blog was written with the help of Mr. Normand Brais: former teacher at l’École Polytechnique de Montréal, mechanical engineer, owner of a master degree in aerothermal and a doctorate in nuclear engineering.